THIS POST IS ONE I WILL UPDATE AS MY JETTING CHANGES.

It starts when the carb is installed on the px200 (LML T5) and is currently on the GL PX 221 with Malossi reed block............ go to bottom for current setup

Ok, now I have installed the PWK Knockoff carby, and I am trying to jet it correctly.

The throttle cable went in easily enough. I already had a japanese style throttle cable anyhow (due to the shop not having a vespa one when mine broke). The choke adaptor was a bit dodgy but I got it done anyhoo.

It's the jetting that will be hard.

I started with the following:

130 main

stock (dunno) pilot jet

jjh needle in middle clip

Screw 2 out

At first I thought it ws all a bit lean as it was flat at 1/2 to 3/4 throttle.

I changed over to a 5th clip(richer) and a 136 main.

On the way home from doing that I felt that it was too rich -too lean-too rich

Tomorrow is plug chop day. I will be tearing up the freeway- a bit at a time.

First stop is needle back to middle notch, 132 main, 2 out.

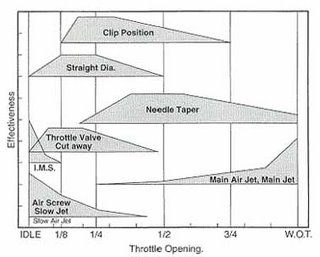

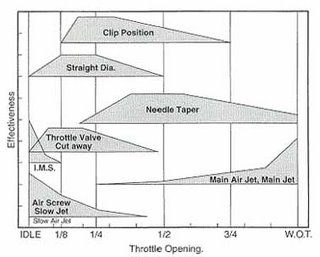

They sent me 15 different main jets, two idle jets and two needles. I think the main jet will be the easiest to sort out... but... I have been studying up on the balance between all the needle elements and other jets, and have some info. Here's a collection of stuff taken from various locations...

It has been a while, but without banging on too much, I have experimented with a fair bit of jetting. After touring Tasmania 2-up I rebuilt the gearbox and since found the jetting to be boggy. I cleaned out the air-filte (foam pod) and changed the jetting from.

LJH 2nd clip

to.

JJK (leaner taper and leaner diameter) middle clip.

It runs great and for the first time has no bog down at 1/4 throttle.

The national rally (over 1000 km's ) is this weekend so I will keep a careful eye on the leanness (CHT guage) and be prepared to pop a richer taper or main jet in before leaving.

I have the following needles in order from rich to lean....

JJF (richer diameter 1/4) middle taper

LJH (middle diameter 1/4) rich taper1/4-3/4

JJH (middle diameter 1/4) middle taper

GJH (middle diameter1/4) Lean taper

JJK (lean diameter 1/4) middle taper - middle clip position - test1a

-2nd clip (leaner) test 2a(JL pipe)

test 1a - 15 km later the thing has great pickup through the rev range. A bit vibrationny at around 5500-75oo rpm. Still to hwy test to see what the main does. (haven't changed it but something seems to have richened everything... maybe the old flyside seal or the exhaust stub were leaking. In fact I know they were).

Now, things have changed again...

I have re-installed the infamous SIP performance (jl I believe) pipe.

It pretty much goes like a rocket without any carb changes which is good.

As these push the useable power higher in the rev range, I will have to now focus on getting the carb dialled in perfectly in the 0-1/3 throttle range. This is because the engine simply wants to get past the low revs as quickly as possible when taking off, and any delay can cause frustration.

Anyway....

TEST 2a - I have dropped the needle (raised the clip) to try and sharpen up the response in the 1/4 throttle area. The bogging/ loss of power in this position could well be due to a too lean clip position, so I am prepared to humbly go the other way later today .

this is a picture of the fron fender from the scootrs website

this is a picture of the fron fender from the scootrs website